Maximizing Effectiveness: Commercial Refrigeration Repair Techniques for Cost-Effective Solutions

Assessing Refrigeration System Efficiency

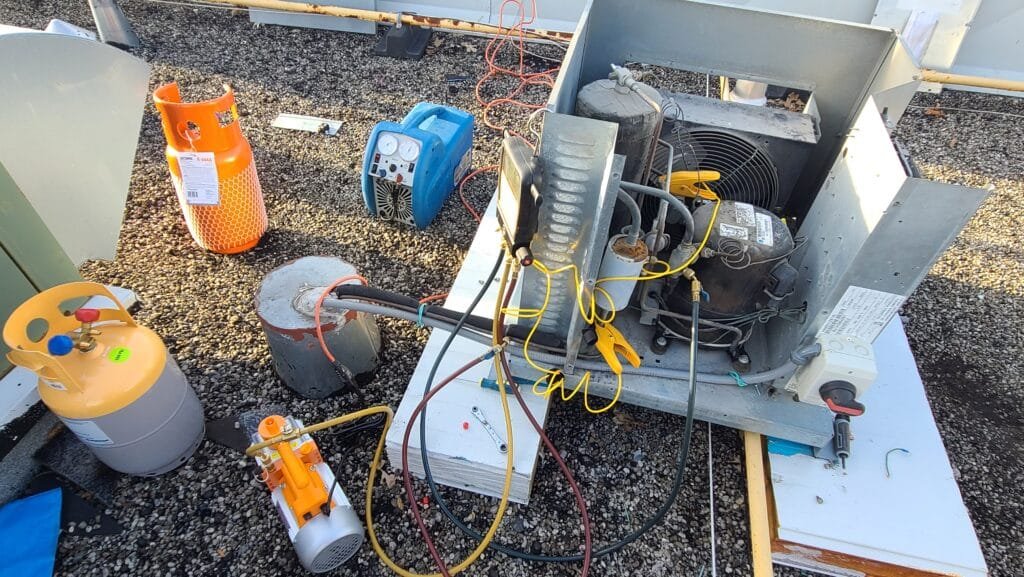

To effectively evaluate the efficiency of a business refrigeration system, it is necessary to perform thorough analyses of its vital parts and operational specifications. The first action in examining system performance is checking out the capability of the compressor.

Checking refrigerant degrees and pressures is likewise important in assessing system performance. Reduced cooling agent degrees or abnormal stress can show leaks or malfunctioning parts that need instant interest to prevent system failings and pricey repairs. By systematically evaluating these key parts and operational specifications, organizations can ensure their commercial refrigeration systems run at peak performance levels, decreasing downtime and optimizing power effectiveness.

Applying Preventative Upkeep Steps

Evaluating the performance of a commercial refrigeration system gives beneficial insights that can educate the execution of preventative maintenance actions essential for maintaining optimum performance and longevity. By establishing a normal upkeep timetable, refrigeration systems can run efficiently, minimizing power usage and reducing the risk of unanticipated failures. Eventually, spending in preventative maintenance actions is a cost-efficient strategy that helps companies prevent pricey repairs and downtime, making certain continuous and reputable refrigeration system performance.

Identifying Common Refrigeration Issues

One of the key aspects in keeping commercial refrigeration systems is immediately recognizing usual issues that might arise throughout their operation. Furthermore, damaged gaskets on doors, resulting in air leakages, can create the refrigeration system to function more difficult to maintain the preferred temperature. By immediately identifying and description attending to these usual refrigeration issues, organizations can ensure the effective operation of their systems and reduce pricey repair services.

Making Use Of Energy-Efficient Fixing Methods

When considering commercial refrigeration repair, carrying out energy-efficient methods is extremely important to enhancing the system's efficiency and decreasing operational expenses. One of the crucial strategies in achieving use this link power performance is making certain that the refrigeration system is correctly preserved. Routine upkeep, such as cleaning condenser coils, looking for refrigerant leakages, and calibrating temperature setups, can considerably improve power effectiveness.

Another energy-efficient repair service method is upgrading to high-efficiency elements - commercial refrigeration repair. By changing older, much less efficient parts with energy-efficient alternatives, such as ECM follower electric motors or LED illumination, companies can minimize energy intake and lower utility expenses. Additionally, mounting programmable thermostats and energy monitoring systems can help manage temperatures better, avoiding unneeded power use

Furthermore, maximizing the system's insulation and securing any type of leaks can additionally add to energy financial savings. Correct insulation aids keep regular temperatures within the refrigeration system, minimizing the work on the system and enhancing total performance. By including these energy-efficient repair techniques, services can not just he has a good point lower their environmental influence yet also accomplish long-term price savings.

Optimizing Refrigeration System Life-span

To make certain the long life and ideal efficiency of business refrigeration systems, preserving energy-efficient repair work techniques is vital, with an emphasis currently moving towards taking full advantage of the refrigeration system life expectancy. Maximizing the life-span of a refrigeration system includes proactive upkeep, timely repair work, and adherence to supplier guidelines.

Furthermore, investing in top quality components and components during repair services and substitutes can enhance the longevity of the refrigeration system. By focusing on proactive maintenance and making use of top quality components, services can enhance the lifespan of their business refrigeration systems, eventually decreasing downtime and functional expenses.

Final Thought

Finally, by routinely analyzing refrigeration system performance, applying preventative upkeep measures, identifying usual refrigeration problems, using energy-efficient repair service techniques, and maximizing the system's life expectancy, businesses can make the most of effectiveness and reduce expenses related to industrial refrigeration repair service. These cost-effective solutions aid to ensure that refrigeration systems run at peak efficiency, inevitably causing increased efficiency and success for companies in the future.

When taking into consideration industrial refrigeration repair, applying energy-efficient methods is paramount to maximizing the system's performance and minimizing functional expenses.To make certain the long life and ideal performance of industrial refrigeration systems, maintaining energy-efficient repair service techniques is essential, with an emphasis currently changing towards optimizing the refrigeration system life expectancy. Optimizing the life-span of a refrigeration system involves positive upkeep, timely repair work, and adherence to producer guidelines.